Not known Factual Statements About forklift lights safety

Not known Factual Statements About forklift lights safety

Blog Article

When navigating inclines or declines, forklift operators need to keep a safe distance in between their trucks and shift at an inexpensive velocity.

What forklift safety lights are necessary by OSHA? Just headlights and taillights? What about blue spotlights or crimson zone LED lights? Sad to say, There's not a simple solution.

Forklift blue arrow lights are comparable to the forklift blue spotlight but have an extra function – they functionality as LED forklift lights, projecting directional arrows on to the ground to signify the forklift's prepared path or path of movement.

These lamps are really resilient and resistant to shocks and vibrations, making them very well-suited to the demanding functioning situations of forklifts. They can face up to rough managing and therefore are not as likely to break— giving dependable lights for extended intervals.

Regrettably, when these incidents come about, it is often the driver who gets harm or killed. To deal with these dangers, drivers need to exercise safe driving techniques and comply with safety protocols to remain safe.

Forklifts have to endure frequent inspections to establish any defects or malfunctions that may compromise safety. According to OSHA, operators really should conduct a pre-change inspection to check for obvious injury or operational problems.

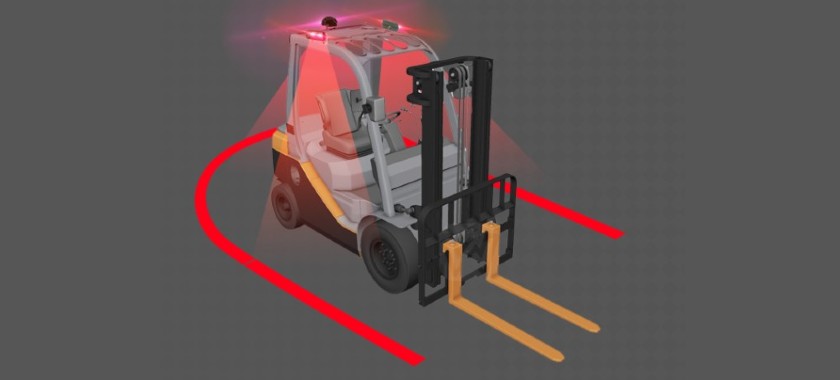

Blue lights mounted on forklifts venture a beam of blue light-weight on to the ground, developing a visible protection spot. The exact projection forklift lights safety and protection may possibly alter according to the style of blue mild utilized and its posture about the forklift.

It enforces several safety polices regarding the use of forklifts. Putting in blue safety lights is usually a thoughtful strategy for just about any Corporation that employs forklifts.

In industrial configurations wherever forklifts and pedestrians cross paths, safety is not just a factor; forklift safety is essential. The results of mishaps in these frantic environments can be detrimental.

Clear conversation: Warning lights communicate important details to Those people all around them. One example is, a flashing crimson gentle might point out that the forklift is carrying a significant load and is going to reverse. This interaction helps Other folks foresee the actions on the forklift and adjust their behaviors.

Each forklift forklift lights safety operators and workers should comprehend the reasons of these forklift safety lights. To create the workplace safer and lessen the potential risk of mishaps and injuries, proper forklift lights safety schooling and recognition strategies is usually carried out.

Inspite of getting all the necessary safety measures and pursuing safety protocols, mishaps happen because operator steps are only 1 element of the general equation. The situation and servicing forklift lights safety of the forklift alone must be successfully managed and in good condition.

Ground markings can be an ideal safety navigation. OSHA requirements emphasize the importance of marking long term forklift lights safety aisles and passageways.

A person important way to avoid incidents is to make use of forklift lighting effectively. Learn the way forklift accidents take place And the way basic warning lights can minimize mishaps Within this guidebook to forklift safety lights.